SUCCESS STORY: GHAZWAN SALIM Brewery and TMCI Padovan

Reliability, efficiency, quick feedbacks and good quality for money: the choice of Bardiani valves for Iraq's largest brewhouse

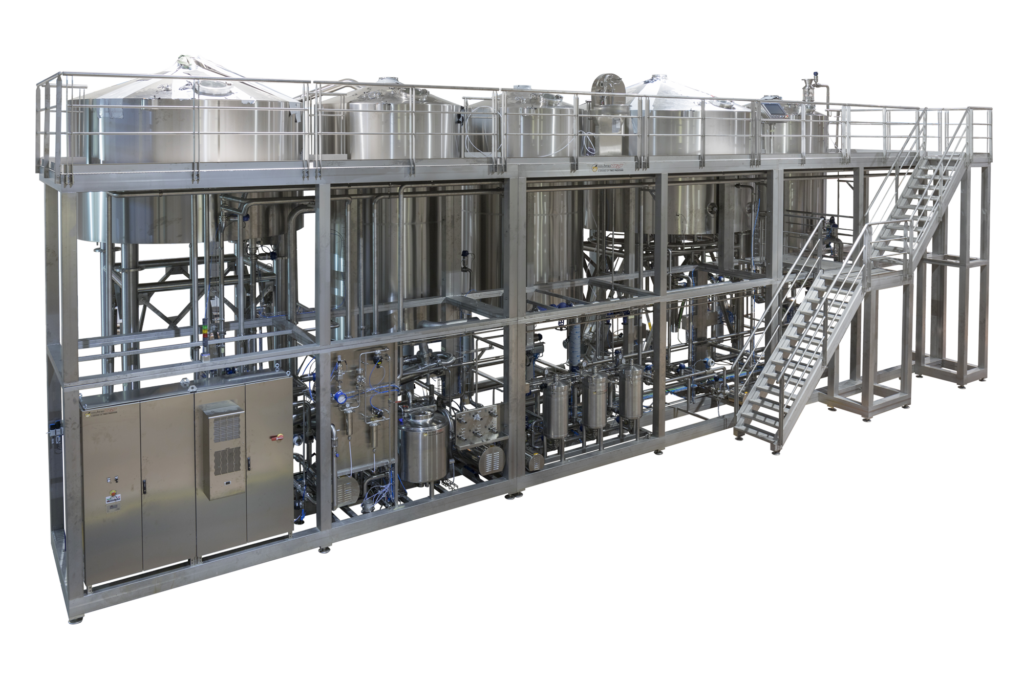

For more than 25 years, TMCI PADOVAN SPA has been choosing Bardiani Valvole services and valves for its installation. For this reason, when the time came to select the valves to be used in the realisation of the GHAZAWAN SALIM brewery, an Iraqi company operating in the field of alcohol production, TMCI PADOVAN decided to rely once again on the efficiency of Bardiani, in this case for an even bigger and more ambitious project. The plant built by TMCI PADOVAN constitutes the largest brewery in the entire area and Bardiani’s valves are once again the protagonist.

The customer: GHAZWAN SALIM

Ghazwan Salim is one of TMCI Padovan’s recent customers and is one of the largest beverage importers to operate in Iraq, in the autonomous region of Kurdistan and is probably to become the largest brewing company in Iraq.

As of 2018, the production of alcohol is legal in Kurdistan and Mr. Ghazwan had been planning to start local production for some time, as he already has previous experience in bottling mineral water.

The brewery, which is currently in the installation phase, will have an initial daily production capacity of 600 hl, with enough margin to reach 1100 hl per day at a later stage.

O.E.M.: TMCI PADOVAN SPA

TMCI PADOVAN Spa is an Italian company, leader in the sectors of food and beverage process technology, divided into 4 business units: Padovan, the historical division of TMCI operating in the oenology sector, Easybräu-Velo, entirely dedicated to the world of handmade and industrial beer, SAP-Blendtech operating in the sector of juices and soft-drinks and Chemtech operating in the sector of butter, margarine, cocoa butter and gelatine.

Customer needs: the quest for reliability, competence and service

Ghazwan Salim‘s main requirement was to identify a partner capable of supplying all the machines necessary for beer production, starting with the milling and handling of malt, the brewing room, CIP and post-fermentation processing machines; and, not least, capable of installing, starting up and servicing in an unstable country.

Since this is the first time a customer has managed a brewery in a country where specific professionalism does not exist for historical-religious reasons, it was therefore essential to identify not only a supplier of machinery, but also a reference from the process point of view. This is why the choice fell on TMCI PADOVAN who decided to turn to Bardiani Valvole, reassured by the tried and tested and very effective collaborative relationship, for a guarantee of reliability and immediate response.

The TMCI PADOVAN and BARDIANI VALVOLE solution: the strengths of a winning partnership

To support the customer in the development of the project, TMCI PADOVAN deployed the consolidated experience in the handmade and industrial beer sector of its Easybräu-Velo division, which identified Bardiani Valvole’s offer as the ideal answer to GHAZWAN SALIM’s needs.

Among the strengths put at the service of the customer was certainly the availability and speed of response of Bardiani’s technical service, which facilitated the pre-sales quotation sales and then the engineering of the system.

For TMCI PADOVAN, the project in question is a particularly ambitious one, with a very large demand for valves and a certain complexity to be managed, also for this reason the technical support was fundamental.

The fact of having a previous relationship of knowledge and collaboration with Bardiani, based on deep trust, was decisive.

What convinced the customer to accept TMCI PADOVAN‘s offer was undoubtedly the same reason why the system manufacturer chose Bardiani Valvole: the unbeatable quality-price ratio that distinguishes Italian manufacturers.

GHAZWAN SALIM collaborates with different European companies in its import business and evaluated several suppliers, preferring however the combination that TMCI Padovan and Bardiani can provide with excellent quality, speed and flexibility of response at the right price.

Given the historical period and the scope of this project, being able to turn to Bardiani Valvole was reassuring.

The Bardiani's valves chosen for the project

In total, the Bardiani’s valves used to build this system – installed on the brewing room, water tanks, filter, saturator, yeast propagation system and the two CIPs for cleaning – are about 230 in a rather wide range from DN25 to DN150.

Within the same machine, there is in fact the need to handle very different flow rates and temperatures ranging from 2°C of beer filtration to boiling at around 96°C.

Mainly ZVF valves with a wafer structure and Giotto unit control were used. Also used were BBZP valves, single seat valves that are characterised by their compact design and valve bodies and plugs made from solid bar of AISI 316L steel.

Thanks to their versatility, robustness and reduced number of contact seals, they can be used in all applications where maximum reliability in the shut-off and diversion of a fluid is required.

In general, in the Easybräu-Velo division, Bardiani’s valves are also chosen because they require little and sporadic maintenance and this is certainly another added value. During maintenance, moreover, Bardiani’s valves do not require special tools and intervention times are reduced, compared to other valves on the market.

End result: reliability over time and guaranteed performance

Although the installation is not yet complete, TMCI PADOVAN has already received very encouraging feedback from the customer, and the outlook for the future is equally positive, as GHAZWAN SALIM is expected to reap the same benefits in terms of quality and performance standards already experienced by many other customers supported by the Easybräu-Velo division.