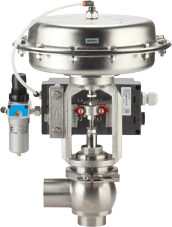

BZZWT1

Aseptic mixproof valve

Main benefits

Manages highly viscous products and large particles

Manages highly viscous products and large particles Safety against pressure

Safety against pressure Aseptic design with single layer diaphragm

Aseptic design with single layer diaphragm No dead zone inside valve body

No dead zone inside valve body Easy maintenance and cleanability

Easy maintenance and cleanability

Descrption

The aseptic double-seat mixproof valve BZZWT1 is designed to separate two different products or fluids without the risk of cross-contamination, ensuring the complete aseptic integrity of the process. It meets the highest process requirements and standards in terms of aseptic performance,

washability, and safety. BZZWT1 consists of four single-seat valves: two main valves for product passage, equipped with a single-layer PTFE diaphragm that creates a hermetic seal to ensure process asepticity; two auxiliary valves for leak detection and management of the steam circuit during the sterilization phase. The aseptic double-seat mixproof valve is the optimal solution for use in aseptic process applications in the pharmaceutical, food, dairy, and beverage sectors. It is particularly suitable for use with viscous products or those containing solid particles.

Caratteristiche standard

Connections from DN25 to DN100

Connections from DN25 to DN100 Seals EPDM, FKM, HNBR and P.T.F.E

Seals EPDM, FKM, HNBR and P.T.F.E PressiMaximum pressure: 10 bar

PressiMaximum pressure: 10 bar

Varianti

Aseptic mixproof valve with

main valve: single seat valves with diaphragm

auxiliary valves: single seat valves

Aseptic mixproof valve with

Main valves: single seat valves with steam barrier

Auxiliary valves: single seats valves

Aseptic mixproof valve with

Main valves: single seat valves with stream barrier and twin stop

Auxiliary valves: single seat valves