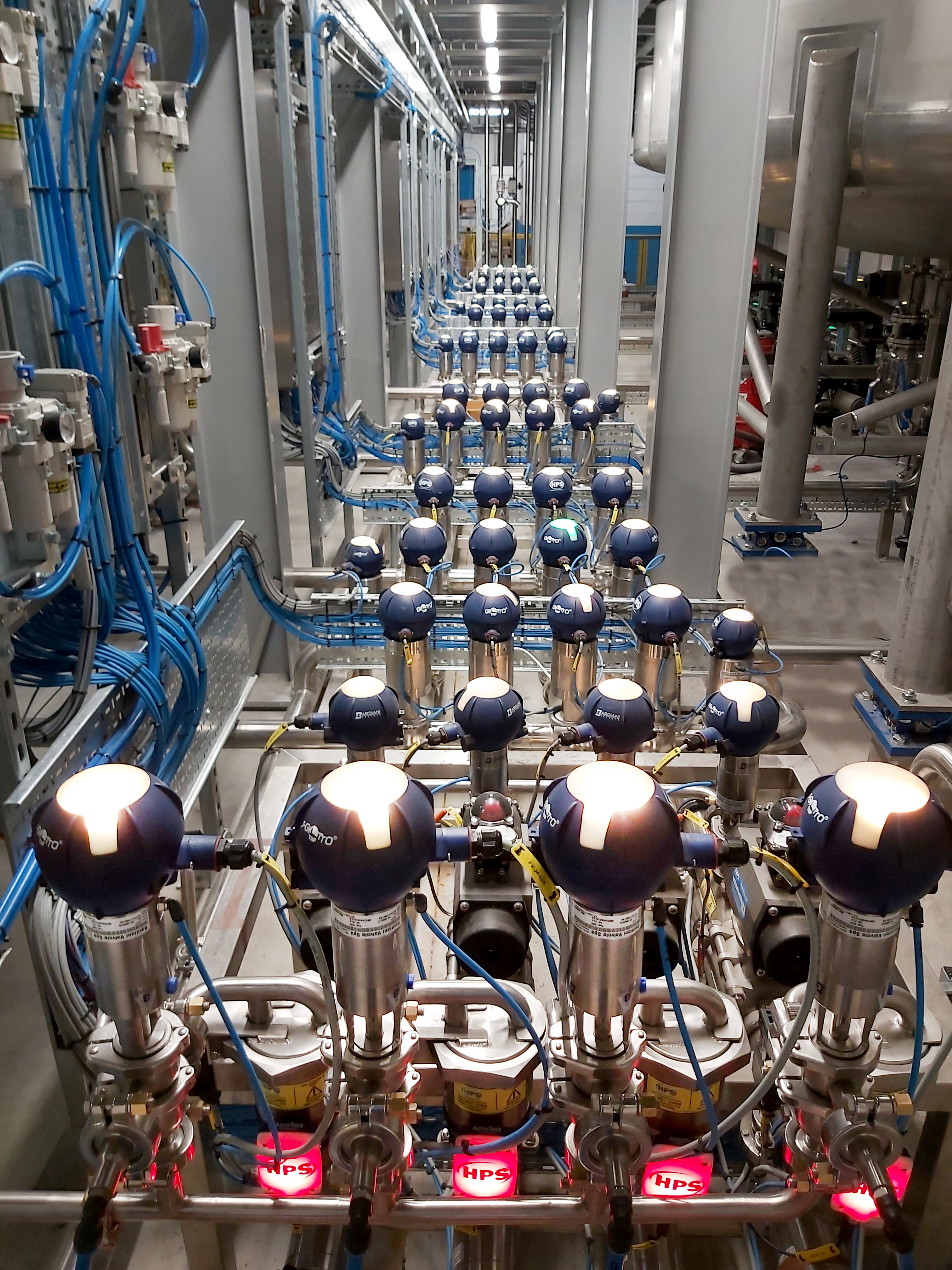

VALVES FOR PIGGING SYSTEM: SUCCESS STORY

Bardiani valves as crucial components in pigging systems: ad hoc solutions to improve efficiency and sustainability of industrial plants

Thanks to the use of Bardiani valves, the customer was able to create a reliable, efficient, highly-performing system and to disposal a complete range of support service. Bardiani valves installed in the pigging systems, allow lower water consumption, lower production costs, reduction of contamination risks, reduction of cleaning processes requiring manpower, lower consumption of chemicals and lower waste disposal costs.

O.E.M.: HPS Product recovery solution

HPS Product Recovery Solution, founded in 1995 and based in Nottingham, UK, operates in the US and in Australia as well. It also collaborates with other Partners, representatives and distributors around the world.

HPS supports its customers by maximizing product performance, reducing waste, supporting environmental sustainability and improving efficiency. All this through the recovery of fluid product (pigging), fluid release and then the transfer of solution for industrial process.

HPS has hundreds of customers around the world and several succesfull systems. It carries out projects for multinational companies such as UNILEVER, P&G, AKZONOBEL, BOOTS, THE COCA COLA COMPANY, CAMPBELL’S, BENJAMIN MOORE, NESTLÈ PURINA, MARS, KRAFT FOODS, and also for smaller ones.

HPS cooperates with a wide range of company operating in a different sector as: food & beverage, cosmetics and personal care, household products, chemicals, paints, coatings, up to the pet food processing sector.

The Customer: an important multinational Paint and Coatings manufacturer

HPS’s customer is a well-known manufacturer of paints and coatings. With more than a century of experience, this company has established as a global leader in that field. Sales in 2021 exceeded $ 16 billion. The company has product plants all over the world in Europe, North America, Latin America, Pacific Asia and much more. It has a very large target including consumer products, spare parts, the aerospace and automotive branch and much more.

HPS has collaborated over the years with this company in many of its agencies around the world.

BBZPPG valves: specially designed for pigging - no obstructions for fast and efficient cleaning

Piggable valves are designed to allow pig transit thanks to the special design of body and shutter. The internal diameter of valve body is the same of the pipe, in order to avoid every obstructions, even when closed.

This feature allows the pig, when pushed through the pipeline, to move easily through the valves.

What differentiates the standard single seat from the BBZPPG is that the last one ensure maximum product recovery. This happens thanks to special design that mimimises dead zone and allow minimal product residue.

It has been developed for applications requiring a high washable level and high hygiene standards.

Bardiani Valvole and HPS: a concrete and successful cooperation

HPS judged this valve as a unique pattern on the market and the perfect one for its customer’s project, confirming once again the worth of the collaboration between HPS and Bardiani Valvole and the high level of service and products developed by valves manufacturing company.

Thanks to the use of Bardiani valves HPS was able to create a reliable, efficient, highly-performing system and to disposal a complete range of support service. Moreover, the use of HPS piggings solutions, which includes the use of Bardiani valves, allows lower water consumption, lower production costs, reduction of contamination risks, reduction of cleaning processes requiring manpower, lower consumption of chemicals and lower waste disposal costs.